Understanding FPC – Structure, Working Principle, and Applications

1. What is FPC?

FPC (Flexible Printed Circuit) is a lightweight, bendable circuit board made of flexible insulating materials such as polyimide (PI) or polyester (PET). It is widely used in modern electronics where space-saving and flexibility are critical.

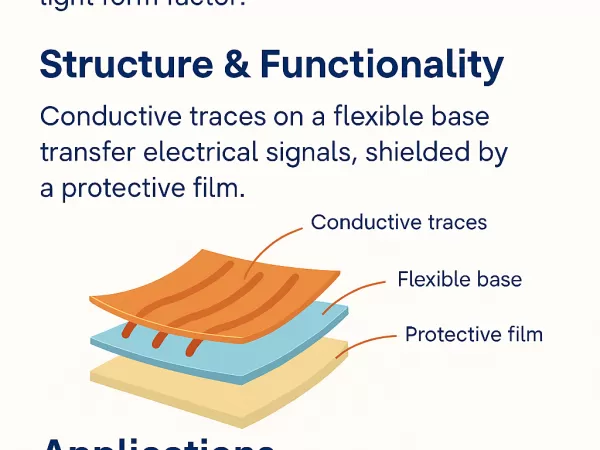

2. Structure

Base Film: Flexible insulation layer that supports the circuit.

Copper Foil: Conductive layer etched into the desired circuit pattern.

Adhesive Layer: Bonds copper foil to the base film.

Coverlay (Protective Layer): Protects the circuit from oxidation, moisture, and mechanical damage.

Stiffener (Optional): Added to specific areas to provide mechanical strength for component soldering.

3. Working Principle

An FPC works just like a rigid PCB—by providing a conductive path between components. The difference is that the copper tracks are built on a flexible substrate, allowing the circuit to bend, twist, or fold without breaking.

4. Applications

Consumer Electronics: Smartphones, tablets, and wearables for internal interconnections.

Automotive: Flexible wiring harnesses in dashboards, lighting, and infotainment systems.

Medical Devices: Compact, lightweight circuits in diagnostic equipment.

Industrial Equipment: Flexible signal and power connections in moving parts.

Conclusion

FPC technology combines electrical performance with mechanical flexibility, enabling innovation in product design. Whether for compact gadgets or complex industrial equipment, FPC is shaping the future of electronics.